Stock Control Software in the Construction Industry: Enhancements from Industry Giant

Managing supply chains in the construction industry is a difficult task. High seasonality, volatile demand, complex logistics, and multi-stage supply chains are just a few of the challenges facing construction company management. Telling the story of one such case study – a client that faced challenging inventory management tasks – can shed light on how it overcame its difficulties and achieved success by implementing new strategies and stock control software.

What were the distinctive features of inventory management in the client company?

When we met the client, we noted that the company had a stable market position, great development potential with unique equipment, and a professional management team committed to innovation. However, the question arose: does the current supply chain management system meet the company’s ambitious goals? A diagnostic was carried out before the project began.

A choice of stock control software: what characterized inventory planning at the pre-project survey stage?

- Complex multi-level supply chains, involving more than two internal warehouses and bilateral product flows. This requires interaction between company branches as suppliers and buyers of different products. Pronounced seasonality leads to significant demand fluctuations and changes in logistics and production lead times, necessitating the need to accumulate and work out volumes for seasonal sales in advance for a smooth load on production capacities throughout the year.

- Production and procurement planning was based on a sales forecast that was not accurate and infrequently adjusted. This irregular process of changes resulted in inflated inventories and a decreased level of service.

- Inventory replenishment planning was carried out manually using Excel without an automatic ordering tool and critical situation indication system. This led to additional efforts by employees and an increased likelihood of errors.

- The production plan for stored products had a fixed planning horizon of one month. Lack of flexibility in changing the plan resulted in low responsiveness to changes in current demand.

- Basic logistic parameters and other data necessary for inventory replenishment planning were incomplete and outdated. Analyzing outdated or erroneous orders caused problems in assessing actual demand.

All of these features, the MRP approach to inventory management and poor process automation led to bimodal inventory distribution, suboptimal cost and turnover, poor customer service and increased inventory management complexity. To solve these problems, the company’s management began implementing the DDMRP methodology and the manufacturing inventory management system – Intuiflow.

More about the business client:

This is in the field of construction and the production of metal materials.

- The company has over 15 production complexes and more than 50 trading divisions

- More than 50,000 regular clients

- The assortment includes 100+ proprietary brands

- Over 4,000 shipments to customers daily

The company’s range of activities covers private construction, commercial and public facilities, sports facilities, production complexes, and trade and entertainment centers.

The high level of company leadership is achieved through:

- The use of advanced equipment and technologies

- Implementing modern approaches to organizing internal business processes, including inventory replenishment management

Before implementing technologies, the company invested in training on DDMRP methodology for its employees from various departments, including top management. This laid the foundation for successfully implementing the methodology principles and the Intuiflow solution.

Inventory management system for a construction company: which branches are chosen for automation and why?

The implementation project was started with one of the four large branches, which includes two production sites and 18 sales units with a managed assortment of more than 7000 SKUs. When working with this part of the supply chain, two levels of replenishment were covered – a regional warehouse with its own production and sales units that receive goods from them.

The choice of this branch was determined by several factors:

- A large region that includes production and distribution facilities.

- Specific features of the branch, namely, climatic and logistical conditions (distance to the central warehouse, long delivery times, road restrictions during certain months). The logic of this decision was as follows: if the methodology can cope with these limitations, scaling to other regions will be just a matter of time.

- The team’s interest in improving performance and openness to innovation.

- The diversity of the warehouse program (different products requiring buffering).

Company goals before implementing a stock control software:

- Optimize the company’s inventory while increasing the service level and accelerating turnover.

- Automate the replenishment process (procurement, planning, production) to eliminate inconsistencies in inventory management, minimize the human factor, and simplify and facilitate the work of employees

- Build a transparent supply chain management system within the selected pilot, based on the principles of the DDMRP methodology

Quantitative effects of the inventory management software:

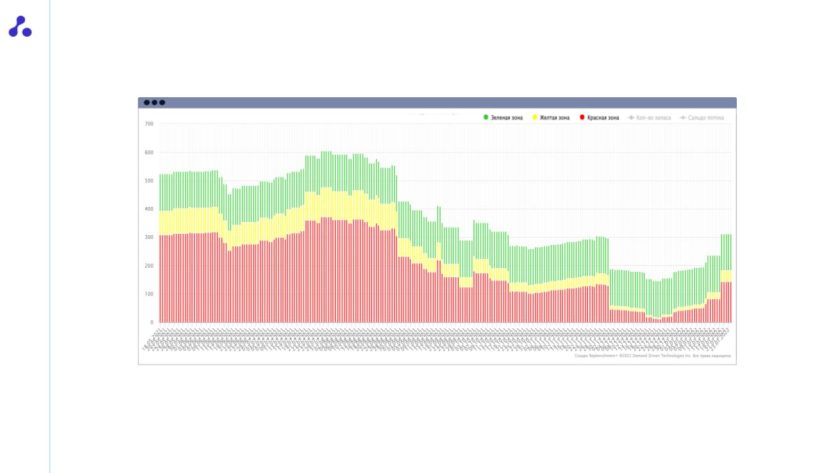

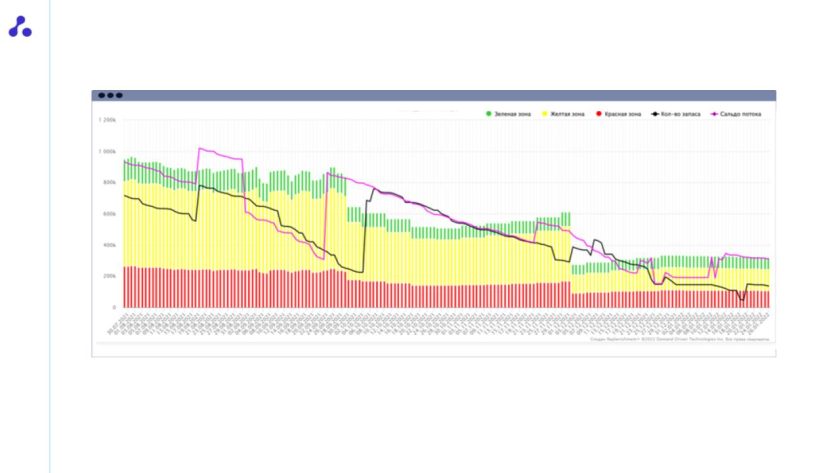

1. Changes in inventory structure. Throughout using the system, there have been significant improvements in the inventory structure of the trading divisions:

- the number of critical SKUs with a risk of shortages was reduced by 3 times

- the number of items with excess stock, which accounted for about 60% of the inventory structure, decreased by 35%

- the share of SKUs in optimal condition (green priority) increased from 15% to 46% (almost 3 times)

The inventory structure has become more “healthy,” secure, and balanced. There has been a shift away from a bimodal distribution.

2. Increasing the level of service by 5% while reducing the balance by 22%. Inventory reduction occurred gradually from the moment the system was launched, during the season (24% reduction), and during the off-season. During the year of Intuiflow implementation, the same level of sales as last year (5% difference) was achieved with an inventory level 36% lower than in the year before the system was used. The level of service in the branch became one of the highest in the company compared to other regions and showed one of the best dynamics for the year (+5%).

3. Acceleration of turnover in days by 35%. Before the project started, the turnover in days at the branch in question was lower than the company’s average. However, during the year of Intuiflow implementation, the indicator became the best among other regions and showed successful dynamics (a maximum decrease of 35%). This trend also improved the average indicator for the holding as a whole.

Quality effects of using the inventory stock management software:

The project also achieved significant qualitative improvements that are difficult to digitize, but their impact is tangible both on the daily work of managers and on the final economic effects.

- Cleaning the assortment matrices. This is the first step to start with, as maintaining a constant stock of items that are not justified in terms of demand can lead to freezing working capital in illiquid assets and irrational use of storage space. The list of active nomenclature was reviewed in terms of demand at a particular warehouse, sales volume and frequency, and the number of customers who order it during the year. The choice of items that should be kept in constant availability at a given storage location is a strategic decision that affects the return on investment in the company. As a result of these actions, the current matrices were optimized and more accurately reflected the needs of the sales divisions. The number of items was reduced by 14%.

- Transparency in inventory management. Since the Regional Warehouse and the sales units it supports are connected to the system, it is possible to quickly and comprehensively assess the situation with any SKU across the network. Where it is in short supply and needs to be replenished, and where it is in excess. The system also focuses the manager’s attention only on deviations and problem areas. Thanks to the prioritization of replenishment, the manager does not need to analyze all the items, the system will pay attention to the necessary ones. Before the implementation of the system, managers did not have enough time to review all the items, so a significant number of them were lost from focus and ordered late when shortages were already occurring. This meant that at least during the lead time, the goods were out of stock, which worsened the level of service for customer orders. Conversely, some items that did not require an order were analyzed and wasted valuable time.

The system of priorities and notifications made it possible:

- Increase the level of stock availability

- Reduce the number of additional orders that were created in case of lack of goods on the balance

- Reduce the time allocated to work with orders

- Reduce order batches and increase their frequency, and thus speed up inventory turnover

At any time, you can also get answers to several important questions about the status of inventory in the supply chain in a few clicks:

- for which items there is insufficient stock and whether orders for their replenishment have been placed

- for which SKUs a predicted shortage may occur, even though there are replenishment orders

- what is the dynamics of working with excess stock, whether overstock is decreasing in quantity and value

- whether managers work according to the system and what is the percentage of order editing

- whether there is enough raw material to launch all the necessary tasks into production

- in which categories, in which warehouses, in the stocks of which suppliers or managers is the main potential for releasing working capital concentrated.

Ability to model scenarios:

The system allows you to model how changes in logistics parameters will affect the target stock. For example, how will the average SKU balance change if we decide to replenish it more often/less often, or switch to supplies from another supplier with different conditions, or instead of managing by the forecasted consumption type, switch to actual past sales or a mixed type.

Thanks to this, the company was able to analyze what stock is expected for specific items under 2 supply schemes – by maintaining the balance at the Central Warehouse and replenishing the regions and with cross-docking (without storing stock for the regions at the Central Warehouse).

From the point of view of the volume of maintained stock and its structure, the option with storage proved to be the best, as it provides for shorter supply leverage, and more frequent orders, i.e. the ability to store less in the regions’ stock and respond more quickly to changing local demand due to the general stock available at the Central Warehouse.

Results from the stock control software operation. How does Intuiflow work in a highly seasonal mode?

During the last stage of the program implementation, the team managed to move beyond the operational level of inventory management to the tactical level, to the medium-term planning plane, using the Sales & Operations Planning module. This module allows you to model the volume of deliveries, production, and the average balance on the horizon for up to 1.5 years.

The applied value of this block is significant because:

- It is possible to estimate how much investment in inventory will be required in the future and how much space these inventories will take up in the warehouse

- You can see in advance the probable future shortages for which you need to prepare

- You have an idea of the estimated volume of supplies that will be received from counterparties or released from production. You can provide suppliers with access to this data so that they can monitor and prepare for changes in the required shipment volumes and increase their level of reliability. And also to production, so that the latter can plan the number of people and shifts that will be needed to produce such volumes.

The last stage of implementation was at the end of the active sales season. The system settings were changed, and the season was exited using the PAF (Planned Adjustment Factor) seasonality factors.

Since sales are seasonal and production capacity is limited, it is advisable to prepare for a sales surge in advance, to load production evenly, and to postpone the production of seasonal volumes to the months preceding the onset of the sales boom. The CDAF (Cycle Day Adjustment Factor) tool was used to increase production volumes in a uniform and timely manner.

Conclusions:

All of these results were made possible by the daily hard work of the entire team, and the desire to deeply understand the principles of the DDMRP methodology and apply them in practice. This process demonstrates how important it is to integrate innovation into management approaches, as it opens up new opportunities to improve efficiency, optimize resources, and increase the company’s competitiveness.