Inventory management metrics in the company

Inventory Management Metrics: Article Outline

Inventory Management Metrics are the process of determining and maintaining an optimal inventory level and ensuring its financing. Inventory management is one of the most underestimated processes for increasing company profits. In the Theory of Constraints (TOC), inventory management metrics are used to assess the efficiency of a link in the company’s supply chain. The primary goal of a product distribution system is to ensure product availability with minimal inventory in the system. Therefore, it is essential to monitor product availability, excess stock, and product obsolescence. Inventory management efficiency metrics are tracked dynamically across periods, locations (stores, product categories), regions, and other parameters.

1. Inventory Management Efficiency Metrics: Availability Level

Product availability is achieved when a supply chain link (store, warehouse) maintains a sufficient stock of each SKU (Stock Keeping Unit). A straightforward way to measure product availability is by tracking out-of-stock levels, that is, those SKUs whose inventory has been depleted.

To calculate the metric, the following data is required:

- Total number of SKUs (Stock Keeping Units) in the product assortment.

- Number of SKUs with zero inventory.

2. Inventory Management Metric: Absence of Excess Inventory

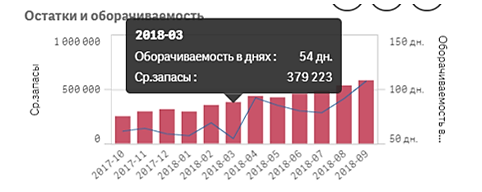

The absence of excess inventory can be expressed through the efficiency of the money invested in inventory. The primary indicator is the rate at which inventory moves. The higher the turnover rate, the more effective the investment. A commonly accepted measure of turnover rate is the inventory turnover ratio.

Through the analysis of this metric, the overall effectiveness of inventory management is assessed over time (acceleration of turnover), and excess goods in the system, which tie up working capital and lead to losses, are monitored. More details can be found here:

To calculate the metric, the following data is required:

- Total annual sales volume at purchase prices.

- Average monthly inventory volume based on the previous 3 or 6 months.

In inventory management terminology according to the Theory of Constraints (TOC), “inventory” refers to the money that a company invests in purchasing what it intends to sell. Therefore, the inventory turnover metric should be based on the purchase prices of the inventory. Inventory turnover should be measured monthly at the end of each month.

3. Inventory Management Metric: Obsolete Inventory Level

Another measure of the efficiency of the money invested in inventory is the obsolete inventory level. Products have their own shelf life. Some items have expiration dates, while others become obsolete when new, substitute products emerge. Consequently, the company is forced to write off obsolete inventory, leading to financial losses.

To calculate this metric, the following data is required::

- Shelf life duration of key SKUs (Stock Keeping Units).

- Amount of money written off each month for obsolete inventory.

- Monthly data on written-off inventory for the last 12 months prior to the implementation of the TOC solution.

The existing inventory in the company has its own obsolescence profile. Implementing inventory management according to the Theory of Constraints (TOC) allows for a reduction of this metric, enabling the tracking of a “younger” inventory and decreasing costs associated with written-off inventory.

Management and senior leadership of companies must understand how well the company performs in terms of ensuring product availability and minimizing excess inventory.

To measure the performance of a link in the supply chain, the following reports are used:

- Out-of-Stock Report: This report shows the percentage of SKUs (Stock Keeping Units) with zero inventory in relation to the total number of SKUs. Monitoring frequency is daily.

- Inventory Turnover Report: The analysis is conducted once at the end of each month.

- Obsolete Inventory Level Report: This report is analyzed monthly or at least quarterly.

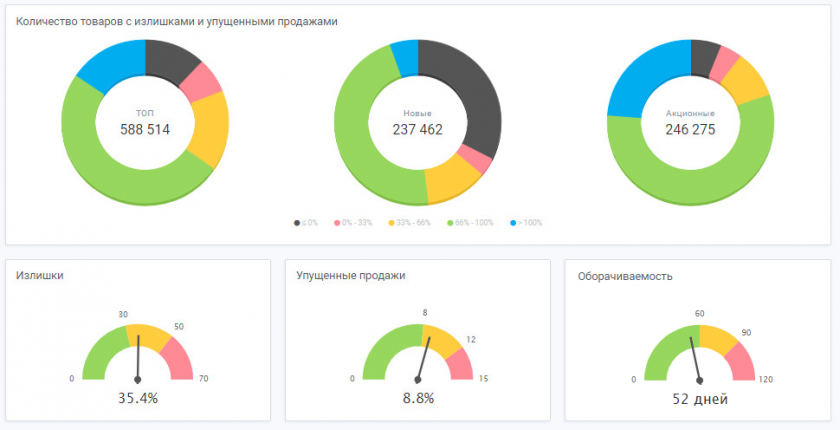

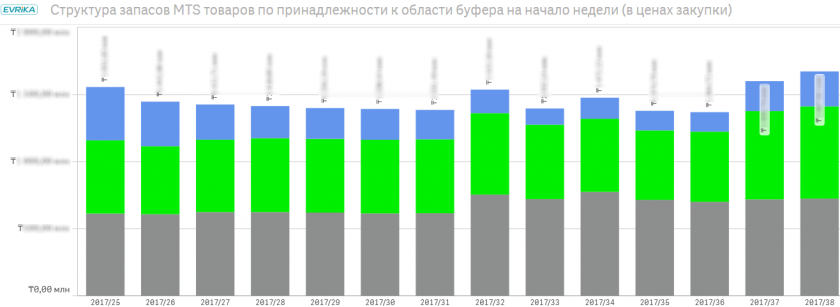

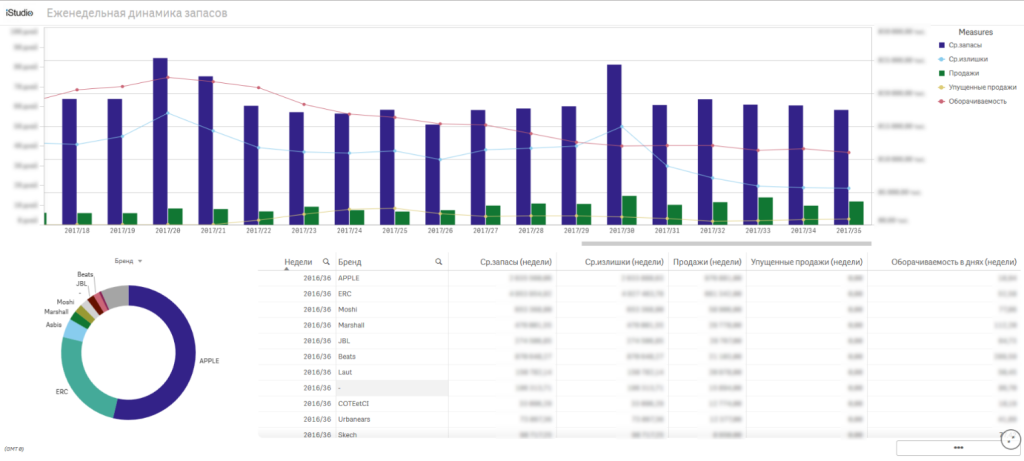

Inventory Utilization Efficiency Metrics

To automatically track and evaluate inventory utilization efficiency metrics, the ABM Inventory software product, designed for inventory management according to the Theory of Constraints (TOC), provides the necessary reports. Key performance indicators are displayed on the dashboard, while detailed reports are generated within the system and sent to the responsible employee via email.