Breaking Stereotypes: How Automation in Category Management is Revolutionizing Retail Networks

The topic of category management remains relevant. Each retailer addresses this issue in their own way: some use Excel, while others opt for software of varying complexity. However, not all retailers and manufacturers adopt a systematic approach. There are many reasons for this, including unrealistic expectations from integration. Therefore, it’s worth delving deeper into the issues related to automating category management and identifying potential pitfalls that may arise during the implementation of such solutions.

When to Implement Automation in Category Management?

There are several reasons why moving towards automation is timely.

It’s Necessary for Both Large and Small Retailers

It is often believed that only large retailers need automation. This is not the case. Smaller chains also have a significant assortment.

Sometimes, in terms of the number of SKUs, they are on par with larger companies, and category managers spend a lot of time on routine processes. In fact, even companies with 5-8 stores face challenges in forming and effectively managing their assortments. The same issues arise for chains with 300 stores.

Therefore, any company that implements automation of assortment processes early on gains an additional advantage in achieving success.

Non-fulfillment of KPIs and Incompatibility of Financial Indicators

A common problem is the failure to achieve key performance indicators (KPIs). This may result from incorrect forecasting, leading to inflated plans. However, it often occurs due to:

- Lack or excess of products;

- An imbalanced assortment matrix (where a product in the store does not interest customers, yet they do not fulfill their desire to purchase something);

- Insufficient control at all levels of the business process, resulting in an imbalance between demand and inventory.

KPIs vary across different networks depending on the type of retail and strategy. For example, indicators for a newly developed category that is just being introduced differ from KPIs for categories that have been functioning in retail for 10 years.

However, common performance criteria are frequently encountered. These include, of course, revenue, profit, turnover, and gross margin (%). Other indicators may also be used: total balances, total write-offs, and others.

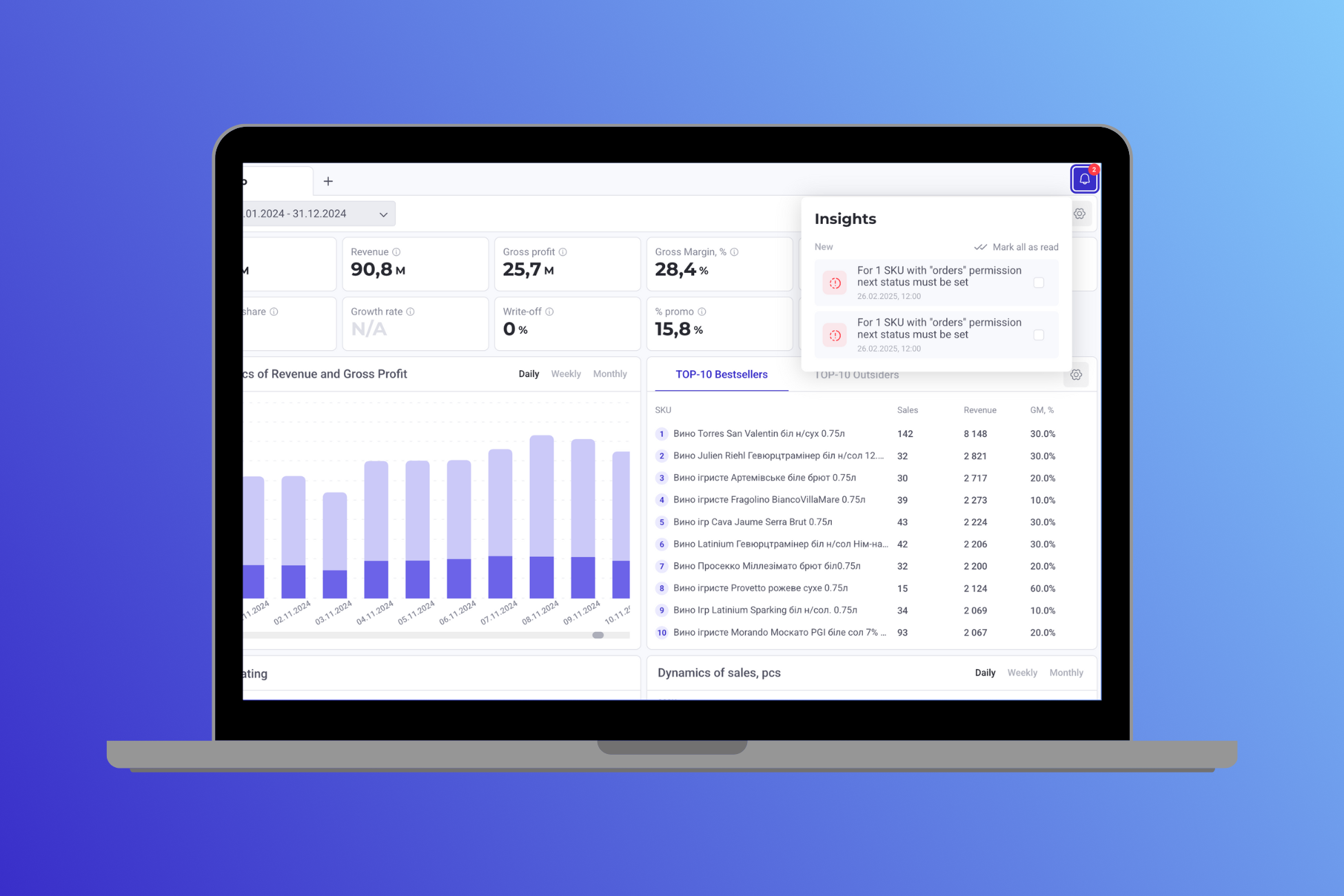

Specialized automation tools not only allow for tracking KPIs but also identify problems within categories. Through data analysis, these tools can pinpoint shortcomings that may lead to incompatibility between demand and available assortment, gaps in assortment filling, or insufficient product variability.

Additionally, such tools generate analytical reports and provide data visualization, enhancing understanding of the assortment’s status and revealing trends. This allows category managers to focus on key problematic segments, make informed decisions regarding assortment planning, optimize purchases, and promote products.

The Need for Quick Problem Detection

Category managers spend considerable time resolving various problematic situations, such as an overall decline in sales within a category. Any problem must be analyzed, and the causes and their relationships with the outcomes clarified. As a result, there is often no opportunity for timely response. Automation helps avoid such “detective investigations” because it allows category managers to receive information about problems promptly and respond to market needs immediately.

This is next-level analytics that enables quick problem detection and informed decision-making instead of wasting time reviewing and analyzing Excel files with thousands of items.

Lack of a Management System: Planning Methodologies and Data Control

This is a fairly common issue, as many companies use standard classifiers and SKU data. However, they do not provide answers to which specific products should be active in particular stores/formats/clusters/regions of large networks with different suppliers and other factors.

Planning methodology can be beneficial if agreements with suppliers are established on key positions once a year or every six months. However, monitoring adherence to these conditions and entry restrictions (such as the inability to order SKUs that should not be in a given store or cluster) and monitoring data effectiveness remain problematic.

Suppose a retail network comprises stores of different formats (for example, hypermarkets, supermarkets, convenience stores) operating in various regional markets. Without a management system, the company may encounter difficulties in planning and controlling the assortment in each specific store. This will lead to lost sales opportunities.

Automation of category management will resolve these issues by implementing a system that ensures more accurate planning, control, and monitoring of data effectiveness. This will maintain an optimal assortment in each store, taking specific conditions and factors into account.

Specialists Rely on Intuition

Many decisions in category management and retail are made at an intuitive level. Specialists often face urgent tasks that require immediate responses. However, a category manager is a person, not a computer capable of quickly processing large volumes of data.

Therefore, it is worth automating this part of the process to instantly obtain specific arguments for informed decision-making.

Manual tracking of changes in demand and assortment

A common belief among managers is, “We have reports and even external services that allow us to analyze data. We think we are keeping our finger on the pulse.” However, this again refers to a manual approach: when a manager reviews analytics only when they feel like it or have the time.

The assortment management system should not merely switch statuses between SKUs and provide analytics that can be reviewed or ignored. It calls for a more systematic, automated approach. ABM Assortment offers automatic insights and suggestions that provide specialists with specific tasks to track factors—even those previously overlooked, such as changes in competitors, availability of alternatives, demand in other business niches, etc.

Category managers spend a lot of time on routine tasks

This is a widespread issue. Typically, they do not have enough time for strategic matters. Specialists are usually responsible for many different aspects. By handling routine tasks and searching for problems in analytical reports, managers waste time and lack the additional resources to tackle important issues. However, this process can be automated, creating a product that takes on all the routine work, allowing them to focus on strategic directions and decisions.

Automation of assortment management: Expectations vs. Reality

Let’s enumerate the most common myths, statements, and expectations that hinder retailers and manufacturers from making decisions about automating assortment management processes.

Expectation: “If we install the coolest assortment management system in the world, it will be able to do almost all the work of the category manager.”

Reality:

This cannot be considered entirely accurate, as a balance is needed. Companies must find their niche and have unique positions that distinguish them from other players in the market. Assortment will never be fully automated. The system will remain a smart tool in the hands of a professional category manager.

It is important to note that a store’s assortment corresponds to specific market demand and reflects customer aspirations. Full automation could lead to the duplication of decisions made by other networks. Thus, only a category manager with deep product knowledge and all its details can create an excellent assortment, equipped with the right tools to do so effectively.

Expectation: “Automation of processes is implemented solely to reduce staff.”

Reality:

We want to dispel this myth (or even the fear of category managers), as the purpose of implementing automation is to enhance the specialist’s competencies, increase sales, improve overall performance, and regularly achieve certain KPIs.

Automation in retail is introduced to improve efficiency and optimize processes, not to replace personnel. Its primary goal is to free the category manager from routine tasks, allowing them to devote more time and attention to strategic issues, data analysis, and making informed decisions. Additionally, automation helps to implement best practices, standards, and optimal processes, which contribute to improved efficiency and goal achievement.

Expectation: “No one can do better than the category manager using familiar tools.”

Reality:

This is only one side of the coin regarding maximum automation. It is worth revisiting the previous points raised about finding a smart balance. It is crucial to understand that processes evolve, new solutions emerge, and ignoring them is not an option.

For example, many people observe the hype surrounding ChatGPT and other AI-based models and have varying opinions about their adoption. However, artificial intelligence truly offers new opportunities. It is similar to exploring the cosmos. There are many intriguing aspects that complement or even replace traditional tools. However, this does not mean it is a magic box where you simply load data, and it “does everything itself.”

In reality, the system only helps category managers move to a new level of management by providing valuable insights and recommendations that no tool can offer. Thus, automation provides category managers with additional opportunities and offers tools that facilitate their work and enhance efficiency in making strategic decisions.

Expectation: “New products are very difficult to implement and learn. They are complex to use.”

Reality:

There is a widespread belief that implementing and mastering new products is always a challenging task, as they often have an unclear interface and require unusual actions to achieve desired results.

>However, in modern conditions, this is a misleading impression.

For instance, ABM Assortment is an intuitive and user-friendly product: even novice category managers can easily understand what they need to do to achieve their goals:

– The interface and functionality are designed with user needs in mind, allowing them to quickly and easily master the system.

– Processes are automated to ensure maximum ease of use.

– The navigation system is well-organized and intuitive.

Expectation: “Solutions always come at a high price.”

Reality:

At the outset of implementation, it may seem that solutions for automating assortment management are very expensive. However, it is essential to view this in the context of long-term benefits.

This involves effective planning, inventory optimization, improved demand forecasting accuracy, reduced product losses, and enhanced ordering and supply processes. As a result, the company can save money, increase sales, and improve overall business efficiency. The market offers solutions with varying price proposals. Retailers can find options that meet their needs and budget.

This is why we adhere to the principle of flexible pricing. ABM Assortment is a cloud solution, and its cost depends on the network’s volume and data quantity. Its implementation allows companies to effectively analyze data, perform strategic planning of assortments and product categories. This contributes to increased sales, improved customer service, and the preservation of the company’s reputation.

Automating category management processes in retail is a necessary step for effective assortment management and achieving a competitive advantage. In today’s market environment, where competition is increasing and consumer demands are changing, manual category management becomes insufficient and chaotic. Automation enables retailers to optimize data analysis, demand forecasting, inventory management, and ensure accurate information about available assortments and their updates. This increases operational efficiency, reduces costs and risks, and allows for quick responses to changes in market conditions while meeting customer needs.