Inventory management in a trading company

Currently, the effective inventory management at a trading company and ability to respond quickly to market changes are the decisive competitive advantages of both the major retail chains and the small “neighborhood” stores.

Inventory in trading is the main capital, thanks to which the trading business exists actually. Procurement managers make hundreds or even thousands decisions every day: what goods to order, how much to order in each position, what is the optimal frequency of orders, how much to order additionally due to a promo action, etc. Company’s profit is inextricably linked with their decisions. But do your employees have a tool that helps them to make effective decisions? Let’s look at a live case about inventory management in a trading company.

How the trading company’s inventory was managed before the project

- Regional chain includes 12 stores, 100 thousand SKU: hypermarkets, supermarkets, and neighborhood stores.

- Inventory management in the company is conducted based on the turnover balance sheet of a separate store.

- Warehouses are bristling with unsaleable goods; money are “frozen” in the products.

- Trading company’s inventory is not optimized: often there were situations with the lack of goods on the shelves of one product and huge surpluses of others.

- The chain was losing sales due to the missing positions and was bearing the costs of storing the surpluses.

- We have here a conflict of interest: managers advocate the increase of stocks, while the stores and the financial/commercial director are pushing the reduction of surpluses and defrosting of money held in stocks.

Objective – inventory management and optimization in a trading company

Commodity stocks of the trading company should bring profits and increase ROI, rather than generate losses and freeze the capital. Therefore, the main objective of the project is to improve the efficiency of the inventory management system at the trading company: to reduce the amount of surplus stocks, to accelerate their turnover, to increase sales by reducing the volume of lost sales.

Inventory management according to the TOC

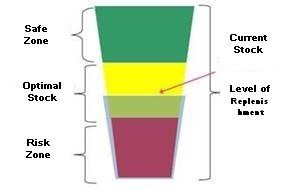

It was decided to implement a specialized program solution for optimization of trading company’s inventory. Monitoring of the system market was performed for this purpose, including the modules within ERP-systems. The ABM Inventory solution was chosen. The advantage and main distinctive feature of this product is that the system manages the inventory based on the actual consumption of the products. This allows you to always have a running product in hand and at the same time keep a minimum stock. The system analyzes and automatically generates orders on a daily basis, based on actual demand. Commodity stocks of the company always correspond to the demand. In order to estimate the daily replenishment algorithm in the ABM Inventory, the TOC methodology (Theory of Constraints) and its tool – the Dynamic Buffer Management (DBM)are used. DBM allows to ensure a high level of product availability with minimal reserves in the system. However, the system automatically performs up to 80% of the daily tasks of the purchasing manager. The manager works only with the problem orders, with facts of non-delivery of goods by suppliers, etc.

Executive staff along with the managers are provided with specialized reports for analysis and managerial decisions on working with stocks, assortment, suppliers, etc. Among the reports:

- Analytics of sales by commodity categories;

- Dynamics of the level of stocks, surpluses and lost sales for each SKU;

- Analysis of lost sales for 6 weeks, for 52 weeks throughout the entire company or warehouse, store, supplier;

- Reliability report for each supplier, etc.

- Also, the system takes into account the seasonality of sales and marketing actions.

ABM Inventory is a cloud solution and works based on the SaaS scheme (system as a service), i.e. it does not require expenses, associated with the installation of additional equipment (server, etc.), as well as the system support.

ABM Inventory was implemented within short timeframes and started to produce results during the first months of its operation.

How did the company’s inventory management change after 3 months

- 3 persons manage 80 000 SKU (except for the fresh group).

- The level of lost sales reduced from 10-12% to 2.4%.

- Turnover of goods accelerated by 7%.

- Supply schedules were reviewed and optimized for many suppliers.

- Assortment matrices were revised – the assortment was optimized; they do not deal with those goods that simply lie on the shelf.

- Inventory management in the warehouse and in the stores is based on real consumption of the goods.

Learn more about the effects of implementing the inventory management systems in companies of various business areas in the ‘Cases’ section of the implemented projects.

Do you want to get the same effects for your company? Request a free demo!