Implementation of automatic ordering and inventory management system the company “Gold Apple”

CUSTOMER BUSINESS INFORMATION

The first shop “Gold Apple” was opened in 1996, Yekaterinburg. Nowadays, the retail chain has 10 shops.

There are lots of SKUs in the perfumery supermarkets “Golden Apple” that are united in a single beauty space. Thousands of clients seek expert advice from the company’s specialists every day.

Besides, company has many employees and according to the words of the leadership they are the basis of business success. The retail chain “Golden Apple” cooperates with the best representatives of the fashion world, especially with make-up artists, hairdressers and top brands like (URBAN DECAY, TOM FORD, ARMANI and others). The management formulates the mission of the company as: “To cheer up girls”.

PREREQUISITES OF THE PROJECT

To achieve operational and financial efficiency of the retail chain, the prerequisite is to monitor key indicators like sales and inventories. On the one hand, inventories should provide a necessary level of sales and at the same time, do not create surpluses. Company needs an appropriate tool for managing and monitoring inventories to achieve such effect.

At the time of the company’s pre-project survey, all orders of the retail chain were formed in a semi-automatic mode with the help of the Dziereri and Excel commodity accounting system.

All the time, company faced such problems:

- no opportunity to see actualized assortment matrices and suppliers;

- the high percentage of errors due to human factors;

- too much work effort made to form orders;

- the overfilled warehouses because of inventory imbalance;

- lack of data on quality of merchandising;

- too many factors which distort the store’s remains;

- human proclivity for counter-insurance, as well as the desire to fulfill the procurement plan led to orders that are higher than needed and, therefore, to excess remains and cash freezing.

These problems had a negative influence on quality of inventory management and, therefore, decreased the efficiency of the entire retail chain. There are no regulations or tools in the company to estimate size and analyze the causes of surpluses and missed sales. In addition, managers usually solve local tasks and do not focus on the company’s global goals.

All of these factors were as an impulse for the top management to implement additional tools to control the level of commodity stocks.

CAUSES OF CHOOSING ABM Inventory

Top-management of the “Gold Apple” company decided to implement inventory management system and gave their preference to systems, which are based on the Theory of Constraints. These systems use the stretching principle and respond to real demand. The mechanism “Dynamic buffer management” ensures that goods are always available, however, with minimal reserves in the system. There were a few important factors which influenced on top-management decision about inventory management system:

- The possibility of optimizing human resources and labor costs for the formation of orders;

- Opportunity to visualize problem areas and current situation with the ability to quickly assess the situation and take appropriate measures.

- The system must have mature technology of implementation with fixed stages, opportunity to consider existing business processes and change them quickly if it is necessary;

- Users must be trained by vendor to know how to work with system and understand management methodology. Accompanying the project at all stages and after it is completed with technical and methodological consultations on an ongoing basis in real time mode.

- No need for additional programming and / or lengthy time-consuming system setup.

The only solution that fully covered all requirements was a comprehensive offer from ABM Cloud, including a product for inventory management – ABM Inventory.

DESCRIPTION OF THE PROJECT

At the beginning of the project, the client set two main goals:

- To create fully automated processing of product purchase.

- To increase inventory turnover.

These goals were conditioned by the fact that, previously, buyers’ assistants spent almost all of their time calculating amount of ordered products and sending orders to the suppliers. At the same time, they tried to fulfill procurement plans which were not always realistic and thus led to overstocking of warehouses, and sometimes to negative profits.

The implementation of the ABM Inventory system began with the education using the inventory management methodology TOC. As this program is based on drawing, the managers had to be flexible and revise their established principles of inventory management.

During the pre-project researchment, was revealed that there is no relevant data about each store’s assortment and the suppliers in the client’s accounting system. A huge amount of work has been done to update this information in order to automate procurement process.

The next step was staff training. We showed how to work with program, what kind of algorithms it has and which settings they can use. Managers were actively supported, we tried to help them to work with new tool as much as we could.

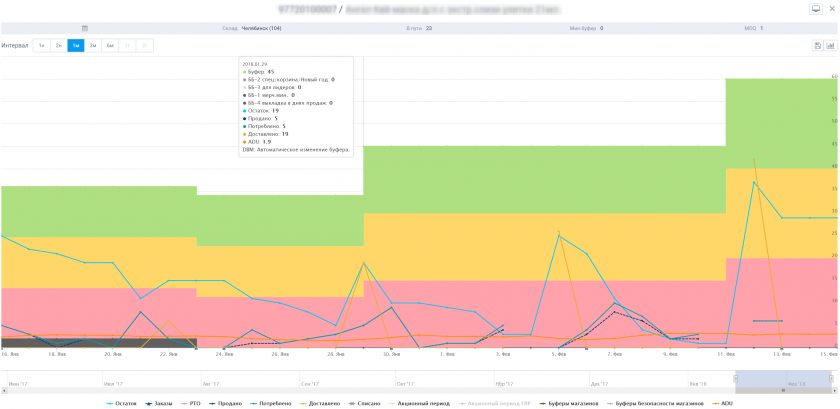

At the first stage (when we were connecting goods to the system), buffers were calculated for each SKU. After several replenishment cycles, the system corrected buffers in accordance to actual consumption of the goods using the “Dynamic Buffer Management algorithm”.

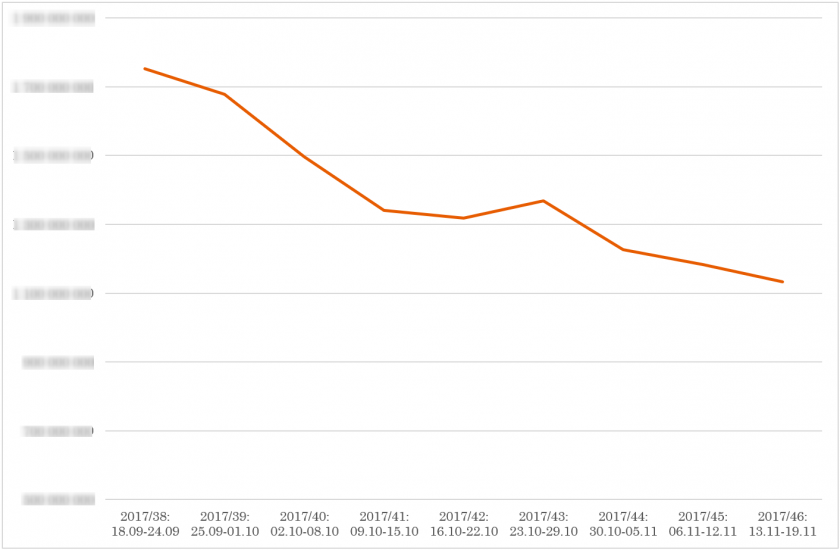

Fig. 1. An example of dynamic buffer management by product

During the project, all major categories of goods were connected to the inventory management system “ABM Inventory”. The system automatically generates and sends orders to suppliers on a daily basis, depending on schedules of orders which were agreed.

Then, in the process of implementation, came out a necessity to identify the areas of responsibility for each manager. Сonsequently, we defined who will be the point person for each product in the store. Also, we calculated an appropriate amount of product that must be on the shelf to make the Presentation Stock attractive. This is especially true in the department of decorative cosmetics, where each SKU has its own cell in special equipment.

After implementation, the “ABM Inventory” is the main space where buyers’ assistants spend their work time and convenient auxiliary tool for employees from other departments. The main screen of system is conditionally divided into 2 parts: on the left, there are daily tasks of manager, on the right, there are key indicators for monitoring the state of inventories and making managerial decisions. At the top of the right pane, there are indicators for goods that require increased attention of manager: TOP-movers, new products, promotional products. They are updated in real time and allow you to monitor the status of stocks in these categories. At the bottom, there are KPIs like surpluses and missed sales in percentage terms and turnover. These parameters are recalculated and updated daily. The usage of color solution allows you to visually emphasize the attention of employees on problem areas.

In addition to the inventory management system, there is also a flexible reporting module. At the beginning of the third stage of the ABM Inventory implementation, managers and company management were trained to work with this system. This module allows you to rebuild reports in real time, to maximize the effectiveness of their use and continuously monitor the state of stocks and related items at different levels of detail.

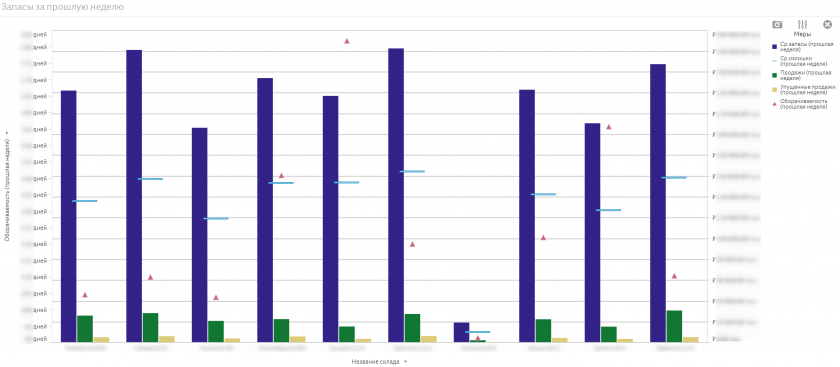

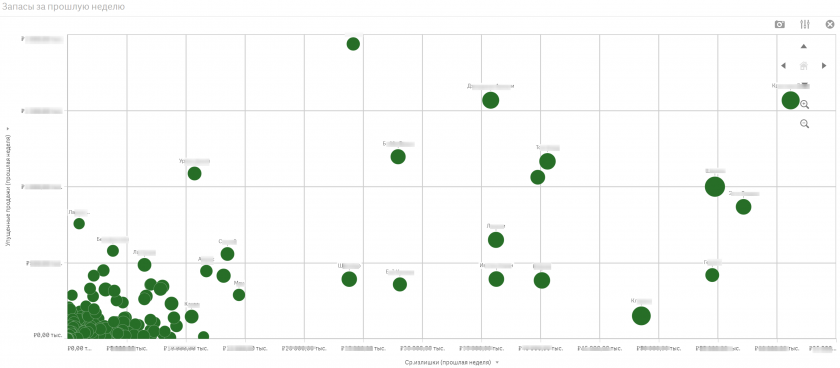

So, with the help of the “Reserves for the last week” report, you can not only compare the basic indicators of stocks in different stores of the network, but also identify leaders and outsiders among the groups of goods simultaneously by 3 indicators, such as: missed sales, surplus and margin.

Fig. 2. Stock level for the previous week 1

Fig. 3 Stock level for the previous week 2

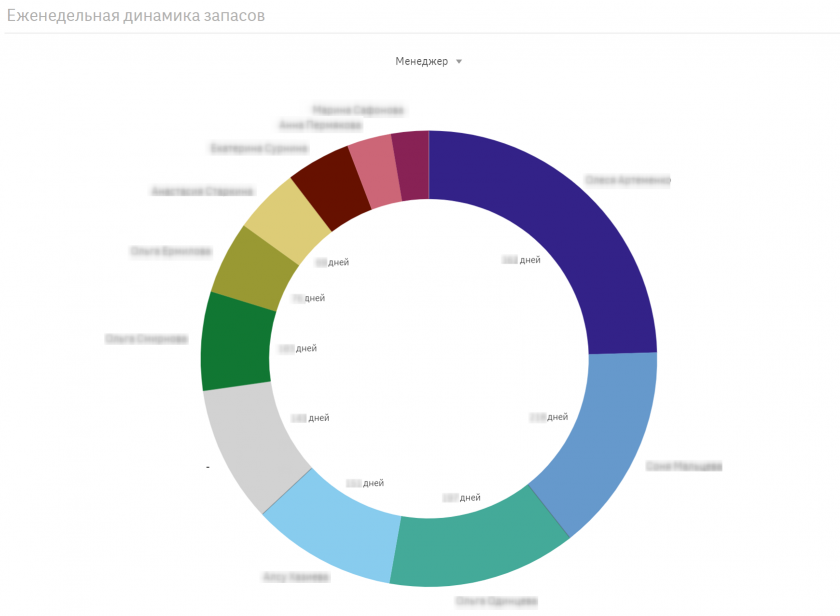

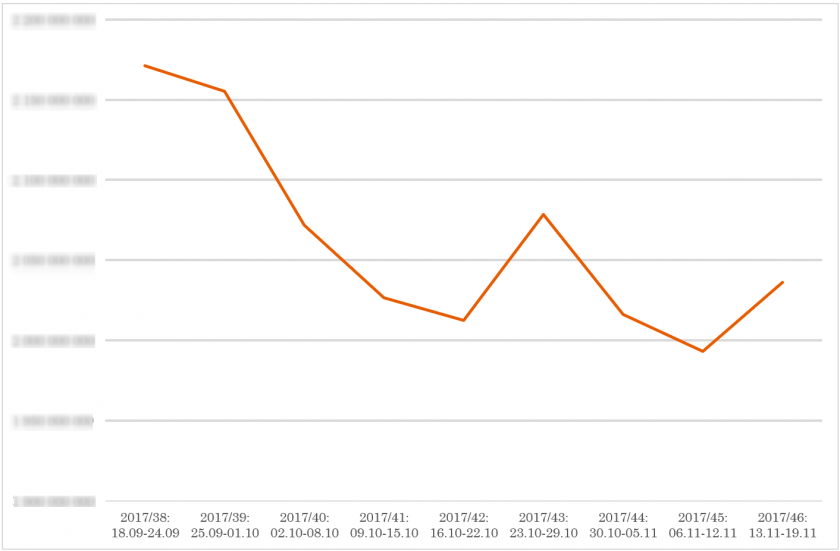

The report “Weekly inventory dynamics” in a couple of clicks can be reconstructed to assess the performance of each of the department’s employees, for example, in terms of turnover.

Fig. 4 Manager’s goods turnover

Except standard indicators of stocks such as the sum of stocks and sales, surplus remainders, missed sales, turnover, the system also estimates how much money is frozen in the calculation of goods, how much in surplus and how much in a zone of the buffer destined directly for sales. For now, at the Golden Apple company in a zone of the safety buffer less than 2,5% of the general stocks are concentrated on the goods operated by the ABM Inventory system.

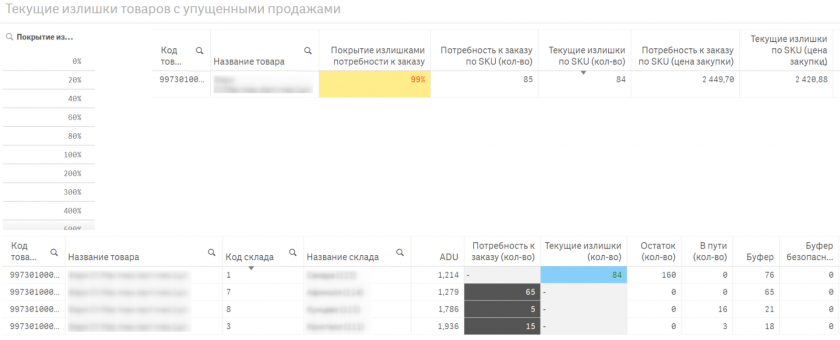

In the company was observed the imbalance of the remains in retail chain, as it was already said in the “Project Prerequisites” section. Therefore, a report, which allows us to see and estimate this imbalance in the system of distribution came out to be very useful. In the given report are leaded out (led out\shown) goods for which there are surpluses in some storage areas with a simultaneous need for other storage locations. On its basis manager can decide not to order goods from an external supplier, but move it from one outlet to another, thus saving the company’s money and improving the structure of stocks.

Fig. 5 Current overstocks together with lost sales

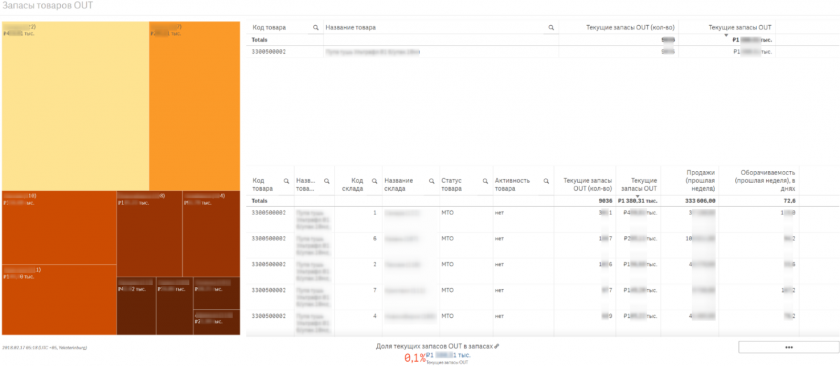

A mandatory condition for an efficient work of the retail chain is the constant updating of the assortment. Dozens of old-fashioned products are removed daily from the network and the same number of new products appears in the range of stores. The ABM Inventory system’s aim is to automate all the main business processes of retail, so it provides the so-called OUT-mover procedure, which frees the manager from tracking the leftovers of each output and does it instead of him. In the reporting module was created the report “The inventory of goods OUT”, which allows you to pay attention to the problem areas.

Fig. 6 The inventory of goods OUT

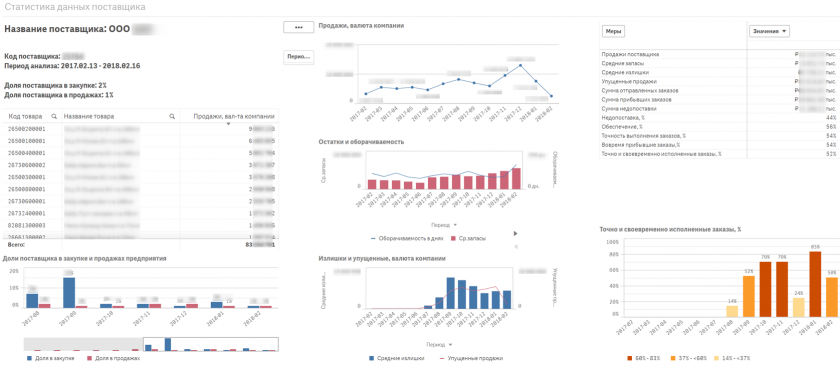

In addition to working directly with stocks, negotiations with suppliers are an integral part of the buyers’ routine.

In order to not waste time collecting information from different places, in the system of inventory management is implemented a report consolidating all the important data which is related to a particular vendor. Among other things, this report allows you to monitor the reliability of suppliers: in it you can see how qualitatively in time and quantity the supplier executes orders (in percentage terms), and the supplementary order report helps to display the picture up to a separate item at the store.

Fig. 7 Statistics about the certain Supplier

RESULTS AND EFFECTS

The centralized inventory management system “ABM Inventory” was implemented in the company “Golden Apple” and manages 97% of the entire assortment. Thanks to the system implementation, the company succeeded:

- Automate the procurement process and:

– reduce the time for processing orders;

– exclude the human factor as the cause of errors;

– automatically send orders to suppliers.

- Establish feedback from stores and increase the effectiveness of interaction with them.

- Carry out a centralized preparation for the New Year and other retail chain’s activities.

- Get fast analytics and visualization of data.

- Analyze the reasons of missed sales.

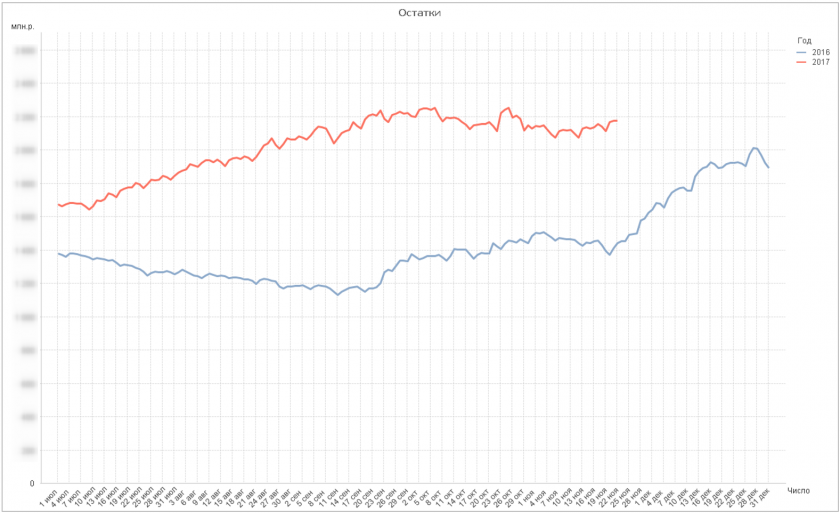

- Reduce network remains.

From the moment of connection of all goods to the system (19.09.2017) to the purchase of goods by the New Year (15.11.2017) the following indicators were improved:

1. Inventories decreased by 7.5%.

2. Surpluses decreased by almost 34%.

3. We managed to stop the trend of continuous growth of reserves, which was observed starting from September 2016.

While preparing for the New Year holidays, the retail chain’s stocks were increased, however, by the time this case was written (mid-February 2018), their level was almost completely restored to the level of October 2017.

We are grateful to the project team for their professional behaviour and productive work done to achieve the set goals. Special thanks to the top management of the company for the active position in the implementation issues, as well as for being open to changes and revising the principles of inventory management, making decisions aimed to improve the efficiency of the company.

We wish “Golden Apple” new opportunities for development and expansion of business, achievement of set goals, successful projects and constant improvement of performance indicators!

Do you want to accelerate the turnover of your stores?

Contact us!