How to effectively manage the Fresh category?

The success criterion for any retailer is having the right product on the shelf at the right time and in the right quantity. When it comes to products with long shelf life and stable sales frequency, the task seems realistic and achievable. And it is, especially if the retailer uses an automatic replenishment software solution. However, the volatility of the Fresh category can negatively impact forecast accuracy, which is why more advanced management methods are required for it.

What are the main characteristics of products in the Fresh category?

Fresh category products stand out primarily due to their short shelf life, often no more than 30 days. This characteristic makes Fresh the riskiest category in grocery retail. The short shelf life is followed by markdowns, which always lead to financial losses for the retailer.

Another key factor is the high share of turnover these products represent. For some companies, it reaches up to 60%, even though the number of SKUs is much lower compared to other categories. Despite having lower margins, these products generate significant sales volumes, driving consumers to return to the store regularly.

Thirdly, the category is distinguished by the specifics of ordering and delivery. For Fresh products, orders are sent at least 1-2 times a week, mostly through direct deliveries from suppliers to the store. Most importantly, logistics plays a key role, as special temperature conditions must be maintained during the transportation of these products..

Features of Fresh product groups

To effectively manage Fresh products, it’s important to understand not only the general characteristics of the category but also what sets the Fresh subcategories apart from one another.

Dairy Products

This subcategory is highly competitive. First, dairy products are everyday staples, making them traffic-generating items. Second, the dairy market is crowded with many major producers, not to mention local ones. This diversity leads to increasing competition between brands. Producers keep prices relatively similar, which lowers margins. The inherent cannibalization effect among leading brands is especially noticeable during promotional activities. Additionally, dairy products have a relatively short shelf life, averaging from 3 to 10 days.- Bakery Products

This subcategory can be compared to dairy products. Bread is also a traffic-generating item, but the difference lies in pricing. Generally, bakery products can be divided into two categories: in-house production and social products. The maximum markup for the social group is 5-7%, while for in-house baked goods, the markup can be 50% or higher. One of the main features of this category is the frequency of orders. Deliveries occur daily, or even twice a day, with a shelf life of about 3 days on average. - Fresh Fruits and Vegetables (FFV)

FFV is a category that includes fruits and vegetables. It’s the most challenging subcategory to manage among all Fresh categories. Seasonality plays a huge role in the availability of different products, resulting in varied pricing policies among suppliers. Buyers compare prices for the same SKU and place orders under the most favorable conditions. In fact, orders for the same product may be placed with two different suppliers within the same week. Another issue that occurs directly in stores is mis-sorting. During weighing, customers may select the wrong SKU code, leading to inaccurate stock records at the store. However, the biggest challenge in managing FFV inventory is the product’s appearance on the shelf and its shelf life. Looking at two units of the same SKU from the same batch, one may already be ready for markdown, while the other still has a presentable appearance.

Meat/Fish and Culinary

These two subcategories share relatively common characteristics, with significant cannibalization during promotional activities. For example, if regular patties are on sale, no one will buy patties with cheese. The same applies to meat or fish: if dorado is discounted, demand for sea bass or trout will drop. Sales are also influenced by product placement. It’s crucial that items are displayed harmoniously and neatly on the shelves.

Another key feature is intra-week seasonality, which depends on the store’s location. For instance, if a store is near office buildings, culinary product sales will be higher on weekdays. A noticeable trend in these subcategories is small leftovers by the end of the day and markdowns after a certain time. Due to short shelf life, retailers are forced to sell off remaining culinary items at discounted prices, such as offering 40% off two hours before closing.

The most important factor, which overlaps with the previous point, is the appearance and shelf life of the product. If the product’s appearance is lost, the SKU won’t sell, even if it’s still within its expiration date.

Analyzing the main features of each Fresh subcategory, it becomes clear that effective management and prompt control of products with a limited shelf life remain a challenge for many retail chains.

How Automation Helps

There is no magic wand that can make Fresh category orders perfectly accurate, or reduce write-offs and lost sales to zero.

Categories like FFV (Fresh Fruits and Vegetables) will never be fully controlled by automatic replenishment systems. The human factor plays too big of a role here. Artificial intelligence cannot spot a crate of mandarins in the store that looks unmarketable even before its expiration date.

However, today it’s impossible to imagine a buyer’s workday without an automatic replenishment system. It helps streamline business processes related to the store’s assortment matrix, promotional activities, and improve key performance indicators for the company:

- Accelerate turnover;

- Minimize excess stock;

- Reduce lost sales.

All of this becomes possible thanks to the optimization of stock structures at each store and warehouse. And most importantly, the system helps automate the creation and submission of orders to suppliers. It’s not only crucial to calculate stock levels using a specific algorithm but also to simplify the entire inventory management process.

The success of accurate stock calculation directly depends on the input data, such as:

- Sales statistics for the product over a specific period;

- Current store matrices;

- Accurate daily stock levels, sales, and receipts for each SKU;

- Information on minimum order quantities and packaging multiples;

- Shelf space allocation in the sales area, checkout zone, endcaps, etc.;

- Updated supplier order schedules;

- Information on remaining shelf life;

- Service Level coefficient;

- Data on the start of promotions for the product.

To ensure the accuracy of all data, the retailer must take all necessary actions to keep stock levels up-to-date and in a sellable condition, including:

- Timely and quick receipting of goods;

- Ensuring early replenishment of products in the sales area;

- Speeding up the movement of goods between storage and sales areas;

- Strictly adhering to product storage conditions;

- Regularly conducting inventory checks and promptly writing off expired products;

- Monitoring product quality and promptly discounting items nearing their expiration date.

All inventory management tasks can be optimized using the ABM Inventory system, which has a special algorithm designed to work with the Fresh category.

How the Fresh Algorithm Works in ABM Inventory

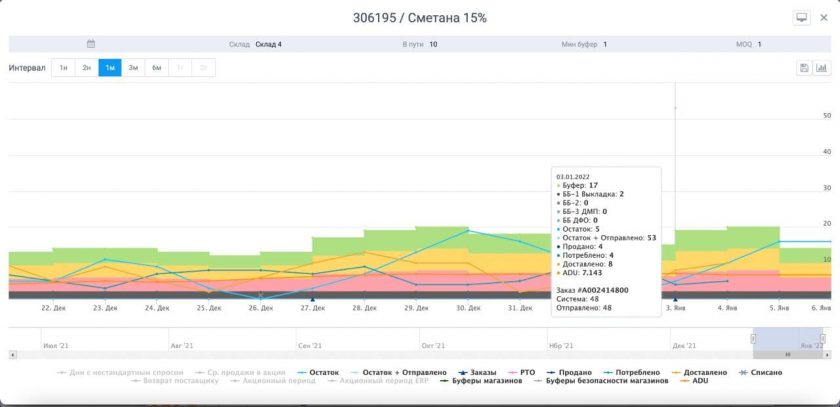

Based on the specifics of the Fresh category, the ABM Inventory system includes a dedicated algorithm. This algorithm is based on sales forecasting and uses advanced methods of mathematical statistics. Below is the logic behind how the algorithm works:

- Calculation of the remaining shelf life and average daily sales, intra-week seasonality (demand elasticity by day of the week), and the service level (Service Level) coefficient.

- Identification of planned consumption from the date of receipt of the current order until the date of receipt of the next order or until the expiration date.

- Determination of the target stock level using the inverse normal distribution function.

- Calculation of the forecasted consumption from the date of today’s order formation to the date of its receipt.

- Calculation of the balance on the date of the order’s arrival.

- Ordering according to the configured schedule.

- Calculation of the Fresh buffer—the target stock level to cover demand and avoid costs.

Managing the Fresh category is a complex process. It not only includes mathematically forecasting the required quantity of goods but also considers all the nuances of merchandising, seasonality, and demand.