How ABM Inventory Helps Choose the Best Supplier: A New Level of Procurement Automation in Retail

Automated Supplier Selection in Retail: Why It Matters

For any retail business — especially in pharmacy and fresh categories — choosing the right supplier directly affects profitability and product availability on the shelves. A single SKU may have several suppliers, each offering different conditions: price, delivery terms, service level, and payment deferral.

Previously, managers often made decisions intuitively or manually compared dozens of spreadsheets.

This took time and created risks: some products arrived late, others were overpriced, and certain stores faced out-of-stock situations.

Now this process is automated.

The new ABM Inventory functionality enables the system to automatically select the optimal supplier based on predefined criteria — quickly, objectively, and transparently.

How Automated Supplier Selection Works in ABM Inventory

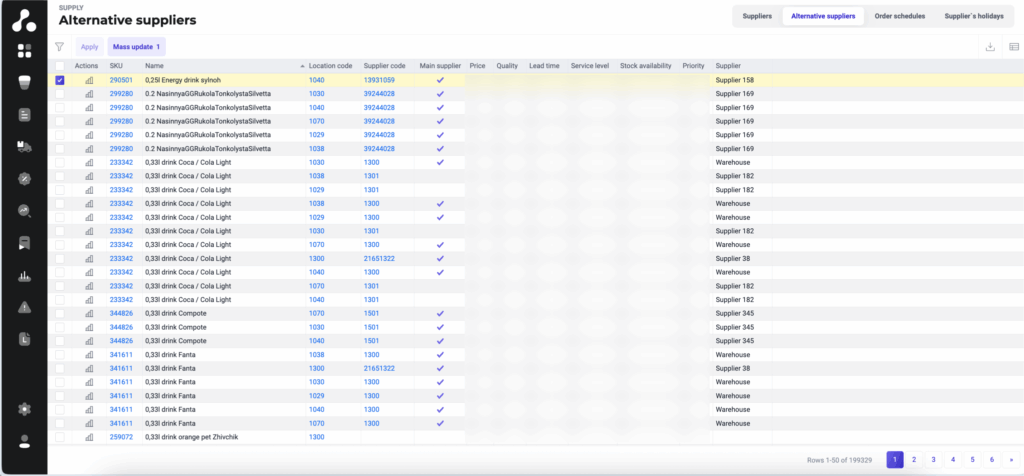

A new tool for managing alternative suppliers has been introduced in the system (Supply → Alternative suppliers).

Users can:

- add a list of suppliers for each product at every warehouse;

- activate the Use alternative suppliers option;

- define selection criteria: price, quality, lead time, service level, and availability;

- assign a weight to each criterion according to business priorities.

The system analyzes the data, calculates supplier ratings, and suggests the most advantageous option for ordering. Calculations can be performed both at the central warehouse level and for individual stores — particularly important for categories with local suppliers.

Automated Supplier Selection Based on Data

ABM Inventory takes into account all relevant factors — from pricing to financial conditions.

For example:

- Supplier A offers a lower price,

- Supplier B has a shorter lead time,

- Supplier C provides a longer payment deferral.

The system evaluates each supplier across all criteria, assigns a rating for each, and then calculates a total score based on the weight of every criterion. Based on this score, the system automatically identifies the supplier that provides the best balance of cost, quality, and service.

Benefits of Automating Supplier Selection

The functionality is designed for categories where supply performance directly impacts results — such as pharmacy and fresh retail. In these segments, profit margins are typically low, so even a small difference in purchase price can significantly affect profitability. That’s why supplier selection should be driven by data rather than intuition — to ensure stable supply and secure the most favorable purchasing conditions. A delay or error in choosing a supplier can lead to stockouts, write-offs, or lost customers.

For pharmacies:

- Optimized purchasing with multiple suppliers. The system automatically identifies the best partner for each SKU.

- Control of critical SKUs. Essential medicines remain consistently available.

- Local sourcing. Regional distributors can be easily incorporated into supply planning.

- Financial conditions. In upcoming updates, the system will also take into account financial parameters — such as payment deferrals, credit limits, and other terms that affect purchasing profitability.

For fresh retail:

- Logistics optimization. The system helps shorten delivery times by selecting suppliers with the most efficient delivery conditions.

- Reduced logistics costs. Through automatic analysis of prices, lead time, and service levels, the company can minimize transportation and storage expenses.

- Fewer write-offs — the system accounts for lead times and shelf life to avoid spoilage.

- Balanced supply decisions — by quality, timing, and availability.

Supplier Analytics and Transparent Procurement Control

ABM Inventory not only automates supplier selection but also provides comprehensive supplier analytics, including:

- performance comparison over different periods;

- adherence to delivery terms (SLA);

- price and lead-time dynamics;

- consistency of service levels (OTIF).

This allows businesses to assess not just individual orders but also the long-term efficiency of supplier relationships.

How ABM Inventory Reduces Manual Work in Supplier Management

ABM Inventory takes over routine tasks — collecting data, comparing conditions, assessing risks — and turns them into actionable recommendations. Managers see the full picture and make decisions based on facts rather than assumptions.

For retail, this means:

- stable product availability;

- fewer losses due to shortages or delays;

- higher profit margins through smarter supplier choices.

Conclusion

The new supplier selection functionality is another step toward complete procurement automation in retail. ABM Inventory considers everything — from pricing and delivery terms to quality, service, and financial parameters. As a result, businesses gain flexibility, control, and transparency in every procurement decision.

Want to see how supplier selection automation works for your retail network?

Request a demo — we’ll show how ABM Inventory helps make accurate, data-driven decisions even in the most complex categories.